Automated Sorting Machine

Automated Sorting Machine

Automated Sorting Machine

Overview

The Automated Sorting Machine was developed as part of the MECH 458 course at the University of Victoria. The project's objective was to design an efficient sorting mechanism capable of distinguishing and categorizing objects based on material and visual characteristics with high accuracy.

Technical Approach

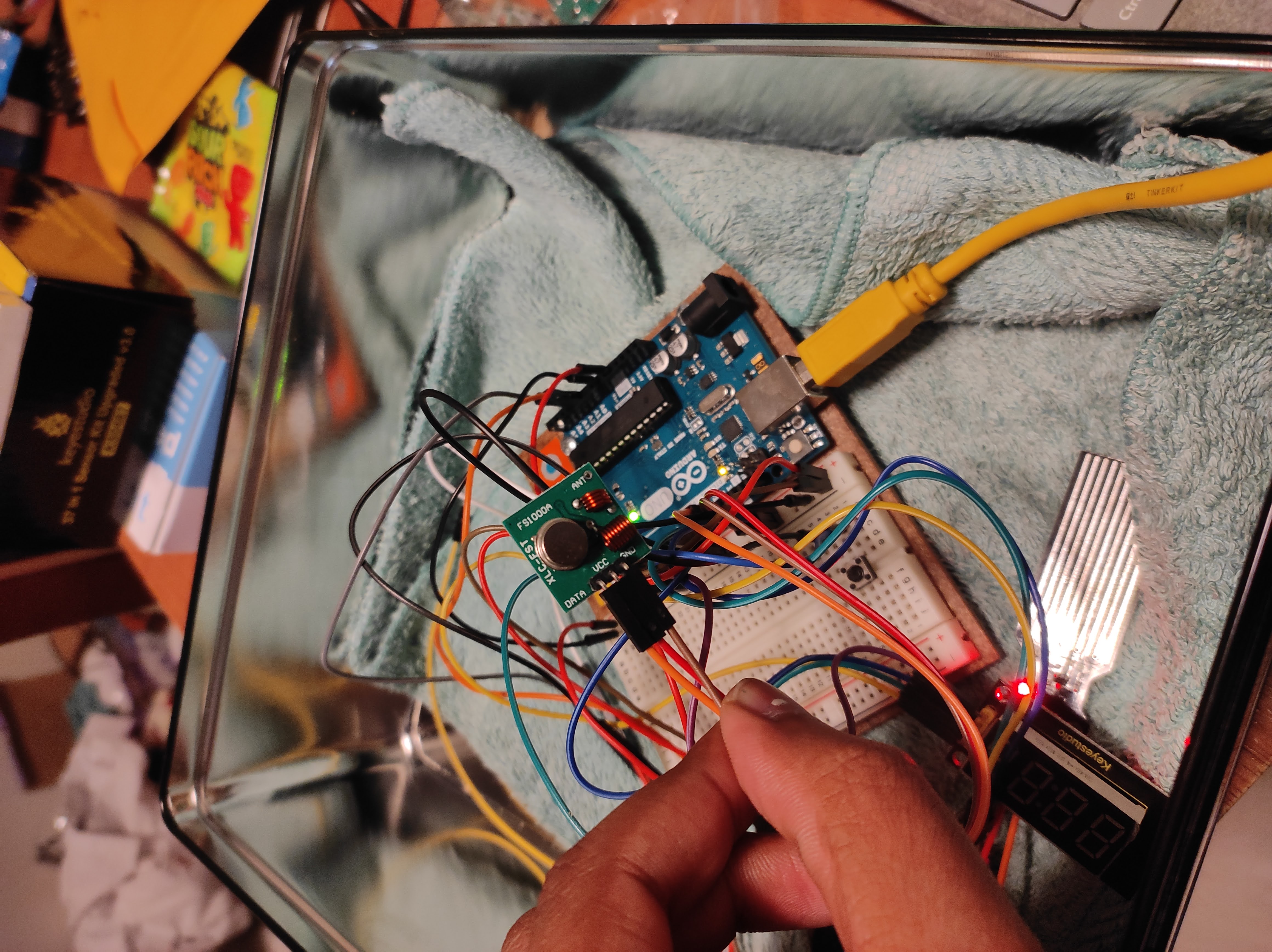

System Components:

Microcontroller: ATmega2560, which controls the operation of all other components.

Conveyor Belt: Powered by a brushed DC motor controlled via PWM signals.

Stepper Motor: Soyo 6V 0.8A used for orienting the sorting tray.

Sensors: Optical sensors for object detection, Hall Effect sensor for magnetic material detection, and a Reflectivity Sensor for material composition.

Control Buttons: System Pause and Ramp Down buttons for operational control.

LED Display: Provides real-time feedback and status updates.

System Algorithm:

The system algorithm orchestrates the sequential operations and decision-making process within the sorting system. The algorithm uses interrupts for responsive control, timers for delays, and ADC for sensor data processing, ensuring smooth and efficient operation.

Initial Setup: The system starts by zeroing the stepper motor.

Polling Stage: The conveyor motor starts, and the system waits for interrupts to switch states.

Sorting Stages: Objects are scanned, identified, and sorted based on sensor data.

Pause and Ramp Down: Features allow the system to pause and safely halt operations, respectively.

Key Innovations:

compute_EF Function: A novel algorithm to enhance sorting efficiency by optimizing the stepper motor's alignment process. This function uses bitwise operations for faster computations, minimizing processing time and enabling quick decision-making.

Performance and Testing

Performance Specifications:

Maximum Operating Conditions: Conveyor belt speed at 70%, handling up to 8 items, with specific stepper motor timings for optimal performance.

Recommended Operating Conditions: Conveyor belt speed at 50% for balancing efficiency and accuracy, handling up to 8 items.

Testing and Calibration:

Calibration: Involved single object testing and determining sensor thresholds for accurate identification.

Edge-Case Testing: Ensured system reliability under various operational conditions.

Accuracy Testing: Quantified system accuracy through repetitive sorting cycles.

Through rigorous testing and calibration, the system demonstrated consistent performance, sorting 48 objects within 37 seconds across multiple runs.

Challenges and Solutions

Limitations:

Sensor Sensitivity: Variability in environmental lighting conditions and object surfaces can affect sensor readings.

Mechanical Wear: Continuous operation can lead to wear and tear, requiring regular maintenance.

Trade-offs:

Speed vs. Accuracy: Balancing high throughput with precise sorting.

Algorithm Complexity: Advanced features add complexity but enhance performance.

Future Improvements

Uniform Feed Conveyor System: Standardizing object placement on the conveyor belt to improve sorting accuracy.

More Powerful MCU: Upgrading to a more powerful microcontroller for integrating machine learning algorithms to enhance system capabilities.

Conclusion

The Automated Sorting Machine project successfully combined mechanical components, sensor technology, and advanced programming to achieve efficient and accurate sorting. The project underscored the importance of practical, hands-on learning in engineering education and set the stage for future innovations in automated sorting systems.

Overview

The Automated Sorting Machine was developed as part of the MECH 458 course at the University of Victoria. The project's objective was to design an efficient sorting mechanism capable of distinguishing and categorizing objects based on material and visual characteristics with high accuracy.

Technical Approach

System Components:

Microcontroller: ATmega2560, which controls the operation of all other components.

Conveyor Belt: Powered by a brushed DC motor controlled via PWM signals.

Stepper Motor: Soyo 6V 0.8A used for orienting the sorting tray.

Sensors: Optical sensors for object detection, Hall Effect sensor for magnetic material detection, and a Reflectivity Sensor for material composition.

Control Buttons: System Pause and Ramp Down buttons for operational control.

LED Display: Provides real-time feedback and status updates.

System Algorithm:

The system algorithm orchestrates the sequential operations and decision-making process within the sorting system. The algorithm uses interrupts for responsive control, timers for delays, and ADC for sensor data processing, ensuring smooth and efficient operation.

Initial Setup: The system starts by zeroing the stepper motor.

Polling Stage: The conveyor motor starts, and the system waits for interrupts to switch states.

Sorting Stages: Objects are scanned, identified, and sorted based on sensor data.

Pause and Ramp Down: Features allow the system to pause and safely halt operations, respectively.

Key Innovations:

compute_EF Function: A novel algorithm to enhance sorting efficiency by optimizing the stepper motor's alignment process. This function uses bitwise operations for faster computations, minimizing processing time and enabling quick decision-making.

Performance and Testing

Performance Specifications:

Maximum Operating Conditions: Conveyor belt speed at 70%, handling up to 8 items, with specific stepper motor timings for optimal performance.

Recommended Operating Conditions: Conveyor belt speed at 50% for balancing efficiency and accuracy, handling up to 8 items.

Testing and Calibration:

Calibration: Involved single object testing and determining sensor thresholds for accurate identification.

Edge-Case Testing: Ensured system reliability under various operational conditions.

Accuracy Testing: Quantified system accuracy through repetitive sorting cycles.

Through rigorous testing and calibration, the system demonstrated consistent performance, sorting 48 objects within 37 seconds across multiple runs.

Challenges and Solutions

Limitations:

Sensor Sensitivity: Variability in environmental lighting conditions and object surfaces can affect sensor readings.

Mechanical Wear: Continuous operation can lead to wear and tear, requiring regular maintenance.

Trade-offs:

Speed vs. Accuracy: Balancing high throughput with precise sorting.

Algorithm Complexity: Advanced features add complexity but enhance performance.

Future Improvements

Uniform Feed Conveyor System: Standardizing object placement on the conveyor belt to improve sorting accuracy.

More Powerful MCU: Upgrading to a more powerful microcontroller for integrating machine learning algorithms to enhance system capabilities.

Conclusion

The Automated Sorting Machine project successfully combined mechanical components, sensor technology, and advanced programming to achieve efficient and accurate sorting. The project underscored the importance of practical, hands-on learning in engineering education and set the stage for future innovations in automated sorting systems.

Overview

The Automated Sorting Machine was developed as part of the MECH 458 course at the University of Victoria. The project's objective was to design an efficient sorting mechanism capable of distinguishing and categorizing objects based on material and visual characteristics with high accuracy.

Technical Approach

System Components:

Microcontroller: ATmega2560, which controls the operation of all other components.

Conveyor Belt: Powered by a brushed DC motor controlled via PWM signals.

Stepper Motor: Soyo 6V 0.8A used for orienting the sorting tray.

Sensors: Optical sensors for object detection, Hall Effect sensor for magnetic material detection, and a Reflectivity Sensor for material composition.

Control Buttons: System Pause and Ramp Down buttons for operational control.

LED Display: Provides real-time feedback and status updates.

System Algorithm:

The system algorithm orchestrates the sequential operations and decision-making process within the sorting system. The algorithm uses interrupts for responsive control, timers for delays, and ADC for sensor data processing, ensuring smooth and efficient operation.

Initial Setup: The system starts by zeroing the stepper motor.

Polling Stage: The conveyor motor starts, and the system waits for interrupts to switch states.

Sorting Stages: Objects are scanned, identified, and sorted based on sensor data.

Pause and Ramp Down: Features allow the system to pause and safely halt operations, respectively.

Key Innovations:

compute_EF Function: A novel algorithm to enhance sorting efficiency by optimizing the stepper motor's alignment process. This function uses bitwise operations for faster computations, minimizing processing time and enabling quick decision-making.

Performance and Testing

Performance Specifications:

Maximum Operating Conditions: Conveyor belt speed at 70%, handling up to 8 items, with specific stepper motor timings for optimal performance.

Recommended Operating Conditions: Conveyor belt speed at 50% for balancing efficiency and accuracy, handling up to 8 items.

Testing and Calibration:

Calibration: Involved single object testing and determining sensor thresholds for accurate identification.

Edge-Case Testing: Ensured system reliability under various operational conditions.

Accuracy Testing: Quantified system accuracy through repetitive sorting cycles.

Through rigorous testing and calibration, the system demonstrated consistent performance, sorting 48 objects within 37 seconds across multiple runs.

Challenges and Solutions

Limitations:

Sensor Sensitivity: Variability in environmental lighting conditions and object surfaces can affect sensor readings.

Mechanical Wear: Continuous operation can lead to wear and tear, requiring regular maintenance.

Trade-offs:

Speed vs. Accuracy: Balancing high throughput with precise sorting.

Algorithm Complexity: Advanced features add complexity but enhance performance.

Future Improvements

Uniform Feed Conveyor System: Standardizing object placement on the conveyor belt to improve sorting accuracy.

More Powerful MCU: Upgrading to a more powerful microcontroller for integrating machine learning algorithms to enhance system capabilities.

Conclusion

The Automated Sorting Machine project successfully combined mechanical components, sensor technology, and advanced programming to achieve efficient and accurate sorting. The project underscored the importance of practical, hands-on learning in engineering education and set the stage for future innovations in automated sorting systems.